|

Piezo

Element

The good points to choose piezo element is that the cost is lower than

others and you can design the sound chamber to reach a special sound.

However, during assemblage, the experienced skill of soldering wires is

strictly demanded, otherwise large defective products such as small sound,

soundless, deviated frequency or electric leakage might happen. Defects

are resulted from:

Piezo element and chamber both have their resonance points.

How to match the two resonance points to get loud SPL and wide frequency

range, the mechanical design has become a test. Material, thickness, size

and depth of the sound hole and the capacity of chamber are the factors

which will affect the chamber’s resonance.

The bad fix method

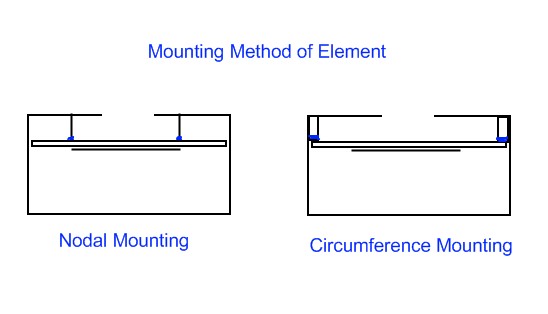

There are two methods for fixing the piezo elements:

Nodal mounting method

This method is to fix the nodal diameter of buzzer element to the supporting

ring of the plate; better SPL can be obtained. Finding the pivot and resonance

frequency of element, then the piezo element will have max vibration and

SPL.

Circumference Fixing Method

This method is to fix the outside circumference of the buzzer element

to the supporting right of the plate. Wide frequency range can be obtained,

and easier to design. For these two methods, flexible adhesive such as

silicon should be used between the buzzer element and the support ring.

Defective soldering

During the soldering, the size and position of the solder point should

be the same. The temperature and pressure should be well controlled to

avoid badly soldering, which will cause short circuit or insufficient

isolated impedance. Besides, the iron need to be separated for the two

solder points, because the ceramic wafer contain a large amount of lead,

using the same iron will cause the fail of RoHS test.

A

& B Components (Taiwan) - Your Acoustic Solution!

Mail us now!!

|